To fit the windstop you will need to remove the T bar, first.

there are three screws along the back edge to remove and then the T bar will pull forward to release 6 plastic plug fixings.

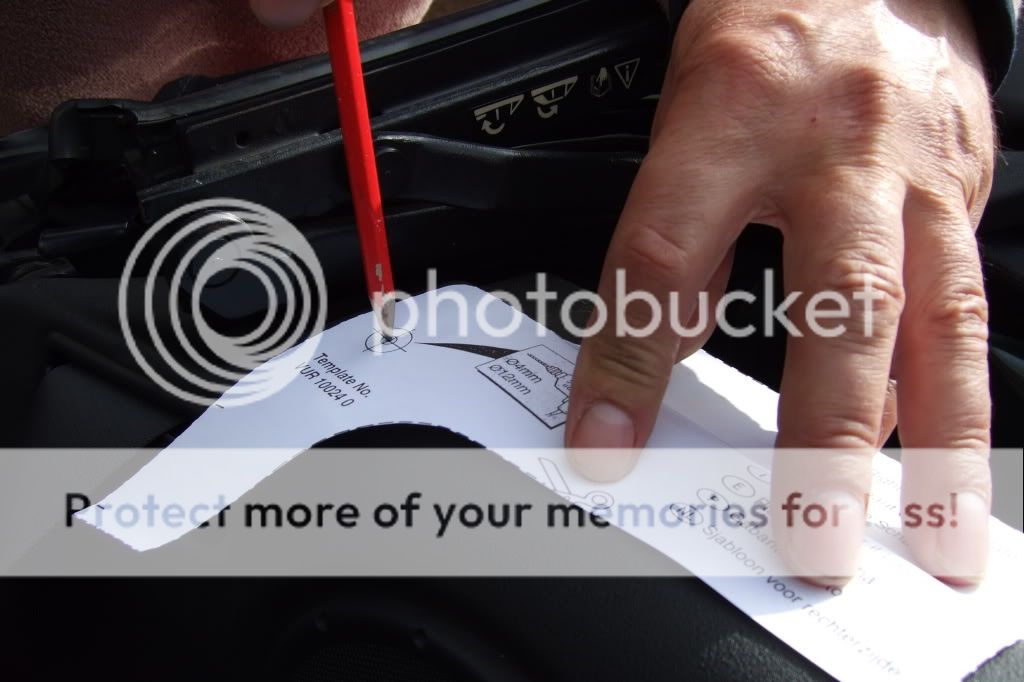

There are two bolts each side of the crossmember / speaker bar(depends on model), and you need to remove the front bolt on each side and replace with the longer bolts from the fitting kit. There is the template to mark the drill holes(above) or you can also do it this way:-

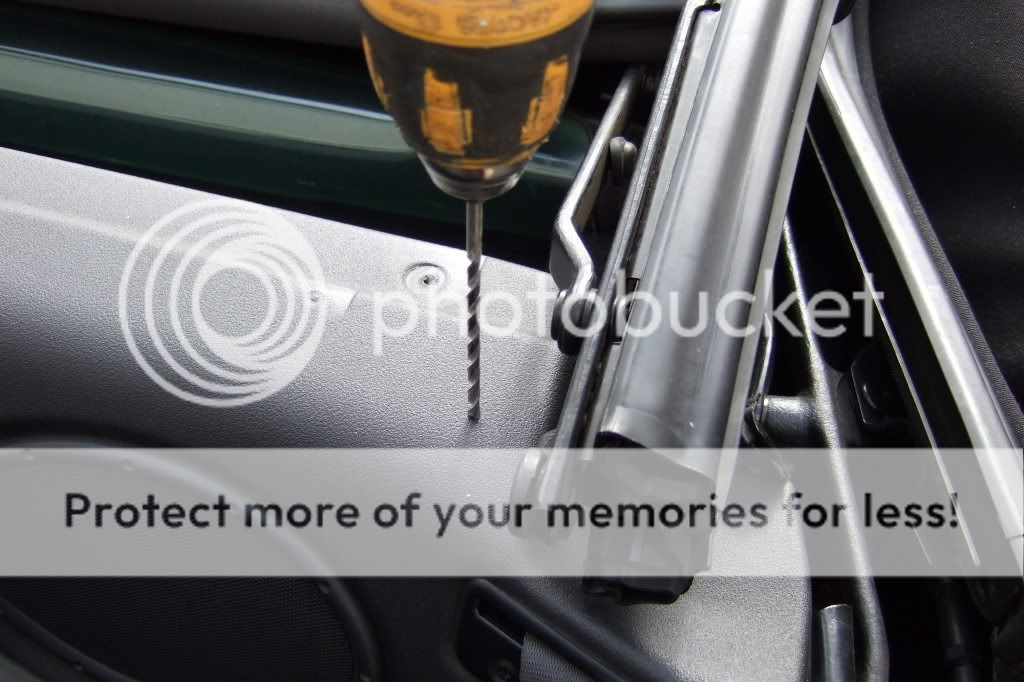

If you leave the long bolts sitting proud and temporarily replace the T bar pressing down onto the bolts. This will give you two marks on the underside to use as guides to drill holes through the Tbar.

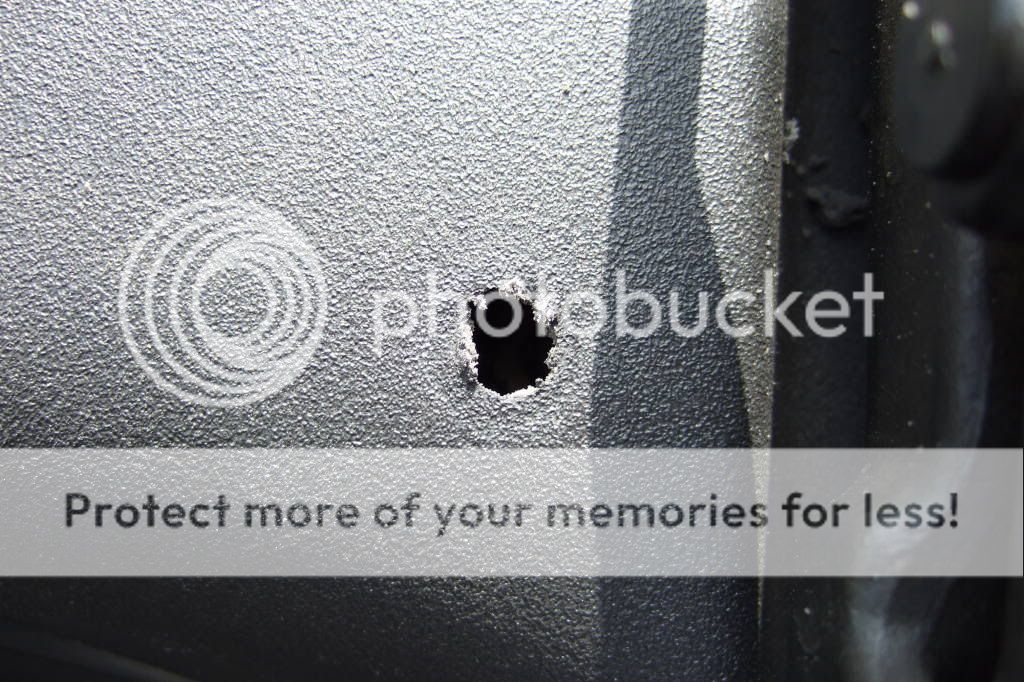

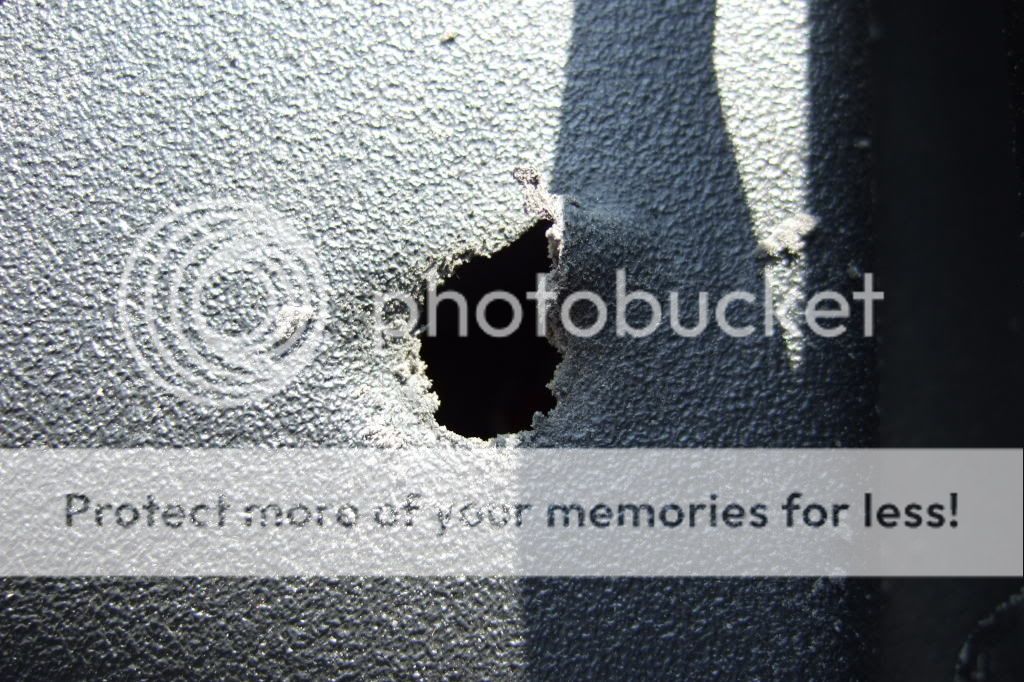

When you have drilled the two holes, check they are in the right place, before removing the long bolts ready to refit the Tbar.

Now you need to drop the long bolt through the black plastic block from the fitting kit. Guide the bolt through one of your newly created holes in The T bar.

Under the tbar slide the black tube onto the protruding bolt and screw the bolt into the empty bolt hole.

Repeat for the other side. Refit the Tbar properly, pushing in the plastic fittings and putting the three screws back in.

Now you can tighten up the two long bolts. Fit the windstop to the blocks and tighten the plastic-headed wing nuts.

Hope that helps.