The Problem?

In order to help the engine breath and increase air flow to improve torque and bhp it has been shown that it is advantageous to replace the standard 48mm throttle body with a 52mm one as fitted to Trophy 160.

The pre 2001 MGF were fitted with an SU plastic throttle body which has had a reputation for sticking due to a distorted body when hot generally caused by over tightening of a jubilee clip on the air filter side.

Later model used a Dellorto alloy throttle body.

52mm throttle bodies are expensive, ranging second hand

~ £70 - £100 and new around

£140+.

How do I know which one is fitted to my car

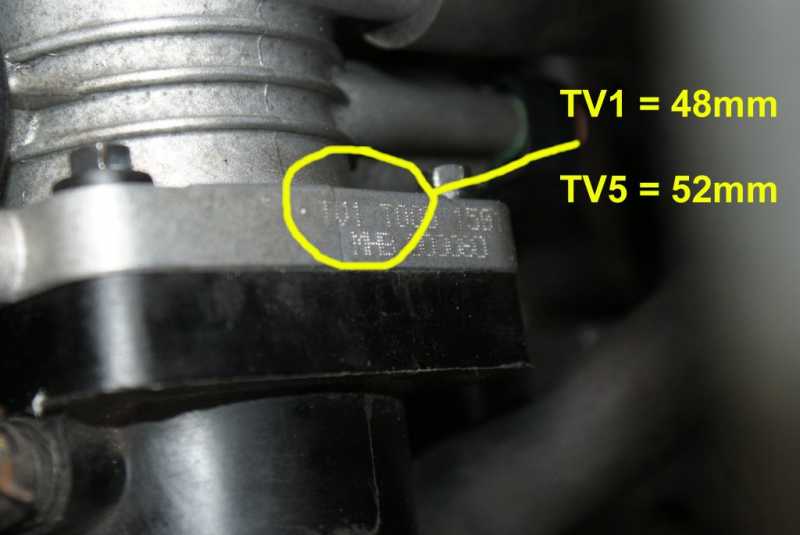

How do I know which one is fitted to my car? Have a look between the air filter and the engine, the one in this photo is an alloy Dellorto throttle body. To the left is the large pipe leading to my K&N 57i filter, this is where you would normally find the standard air filter

If the throttle body is black plastic it is the SU 48mm. If it is alloy then on the upper edge you will find a code engraved on it with one of two codes

TV1 indicates a 48mm and TV5 indicates a 52mm throttle body.

More information on this subject can be found

Here

Tools needed:

8mm socket on an extension, 8mm spanner, screw drivers, file, emery paper, solder, ceramic tile or other non metallic heat resistant flat surface

The Fix

You can

modify your 48mm throttle body free of charge and the work is quite easy to do and can be completed in less than one hour. The results are an improvement over the standard 48mm version and the modification to the 48mm Dellorto detailed here is a popular modification made by Lotus Elise owners.

The modification involves the removal of the wedge attachment and filling the fixing holes. This wedge is fixed to the butterfly in order to soften the throttle response, to make the engine response more subdued at low revs. This wedge does however greatly restrict the air flow.

Depending on which throttle body you have follow the appropriate insttructions

The

how to for the SU plastic throttle body can be found

Here

.

This is an excellent thread with lots of additional information and so I feel there is little point repeating it in this thread.

Note:The modification of the plastic throttle body is shown with quite a bit of work on the actual body as well as the butterfly. It is up to you how much you want to modify the body, but the vast majority of the gains will be achieved by just modifying the butterfly

Dellorto Alloy Throttle Body

After opening the boot and removing the wire cover the modification of the Dellorto throttle body starts with the removal of the unit which is attached to the air filter by a jubilee clip and to the plenum by 4, 8mm bolts.

The two bolts nearest the rear of the car are quite simple to reach with a socket on an extension and wrench, however the other two I found needed to be loosened with a spanner. Once loosened they can then be unscrewed by hand.

All that remains to complete removal is to disconnect the two rubber hoses, the throttle sensor plug and the throttle cable, which is held by the end of it by a T piece which needs sliding out.

If you require a pictorial guide to this refer to

this article

With the throttle body removed you can now remove the metal wedge

Next you need to unscrew the two screws holding the butterfly to the spindle

To release the butterfly rotate the spindle 90 degrees, the butterfly disc will now just slide out

The disc now needs to be prepared for soldering by cleaning in and around the mounting holes which are no longer needed.

I used a blow torch to heat the disc but you could hold the disc in pliers and heat it over a gas cooker. The disc needs to be hot enough so that solder will readily melt and so fill the holes.

To do this place the heated disc on a tile or other non metallic flat surface and then touch the inside of the holes with the solder allowing it to melt and fill the holes.

Once cooled the area around the filled holes may be sanded smooth.