DeepBlue failed its MOT last week and one of the reasons was a badly corroded brake line, in the engine bay, from the 3 way tee to the nearside rear brake flexi.

So I set about replacing the brake line.

I thought this would be a complete nightmare due to the location, but it turned out not to be so bad.

What did become obvious was that the unions weren’t going to come off easily. They were well and truly rusted into place and the 11mm brake spanner wasn’t going to do the job.

What I decided to do was cut the brake line immediately after the unions and then I could get an 11mm hex socket on the union.

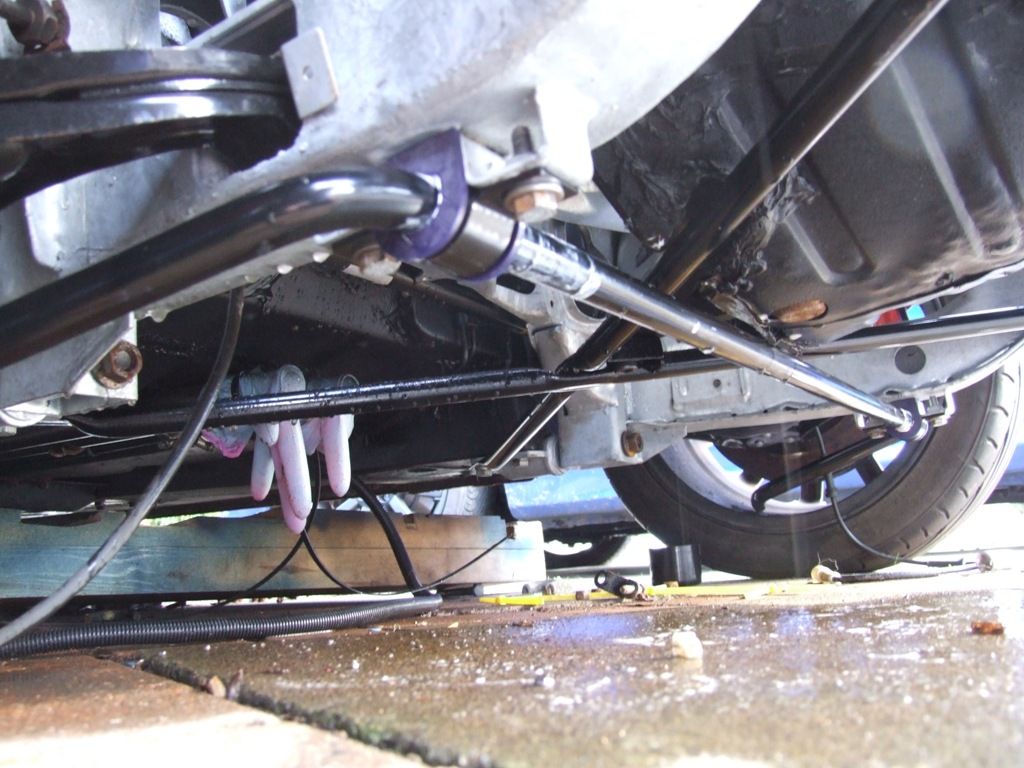

First, you should jack up the rear nearside and support and chock the vehicle. Never work under the car with just the jack taking the weight.

Next, remove the wheel to give better access.

There is an axle stand under there, you just can’t see it.

Now drain the brake fluid into a container, being careful not to spill it onto paintwork, skin, tyres, brake discs…… Well, anything really.

Now we can cut the lines. Obviously, if your unions aren’t stuck then you can just unscrew them.

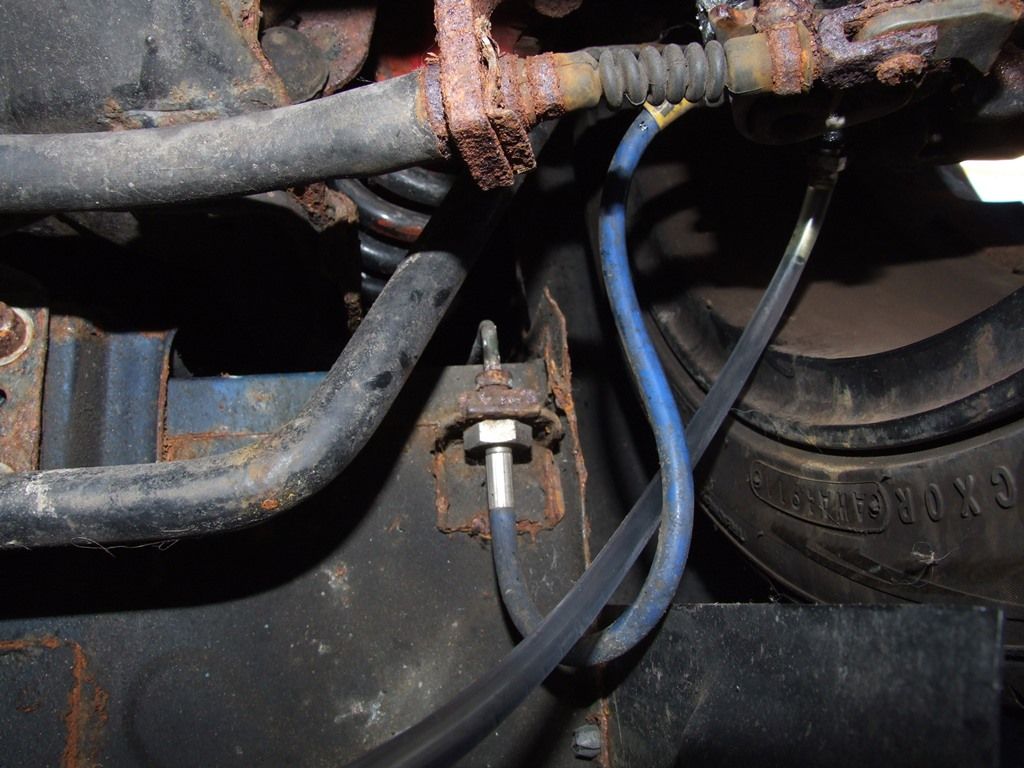

As said, one union is at one end of the brake flexi

And the other end is in the engine bay, on the nearside of the bulkhead.

Clearance is a bit limited, so I whipped out the Dremel. That went flat, so I whipped out the cheap Dremel copy.

Cut the pipes as close to the unions as possible

And remove the brake line.

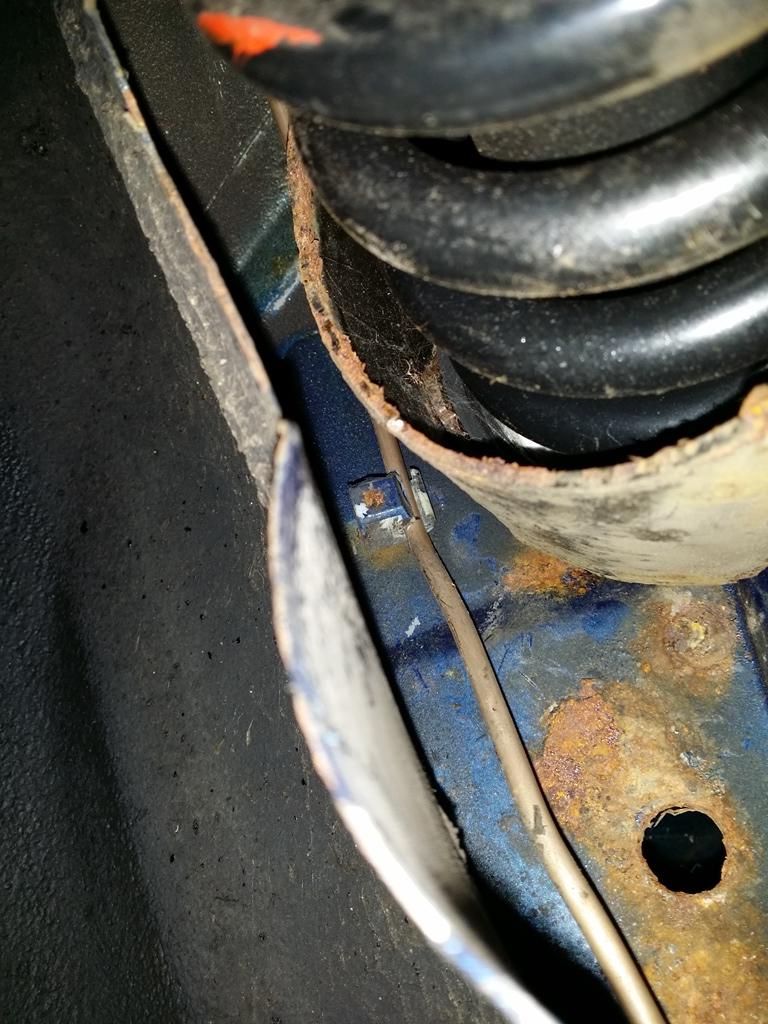

It is held in place by 2 plastic clips up under and behind the wheel arch.

It helps if you look up and see which way to pop the line out of the clip.

You might need to manoeuvre the old brake line out through the wheel arch. Try not to bend it and keep the old brake line as a template to make a new one.

The unions should now be easier to remove with the hex socket.

You will have to support the other end of the union with a suitable spanner (19mm for mine) and be careful not to rip the Tee off the bulkhead.

Now it is time to make the new brake line.

I have posted this before, but I will add it again if anyone is interested.

To try and stop the brake unions corroding again, I bought some stainless steel unions

The unions are Male M10 x 1 and were £1.50 each. I got them from here

http://ccsfasteners.co.uk/stainless-brake-pipe-nuts-c-124.html?osCsid=86927be7fdb3755ae00e8678ed6d5f3c

And 25ft of Kunifer/Cunifer (Cupro Nickel) brake line.

The Kunifer brake line is slightly harder to work with and flare than standard copper brake line, but it is also more resistant to corrosion. If you plan on keeping the car then I would choose Kunifer.

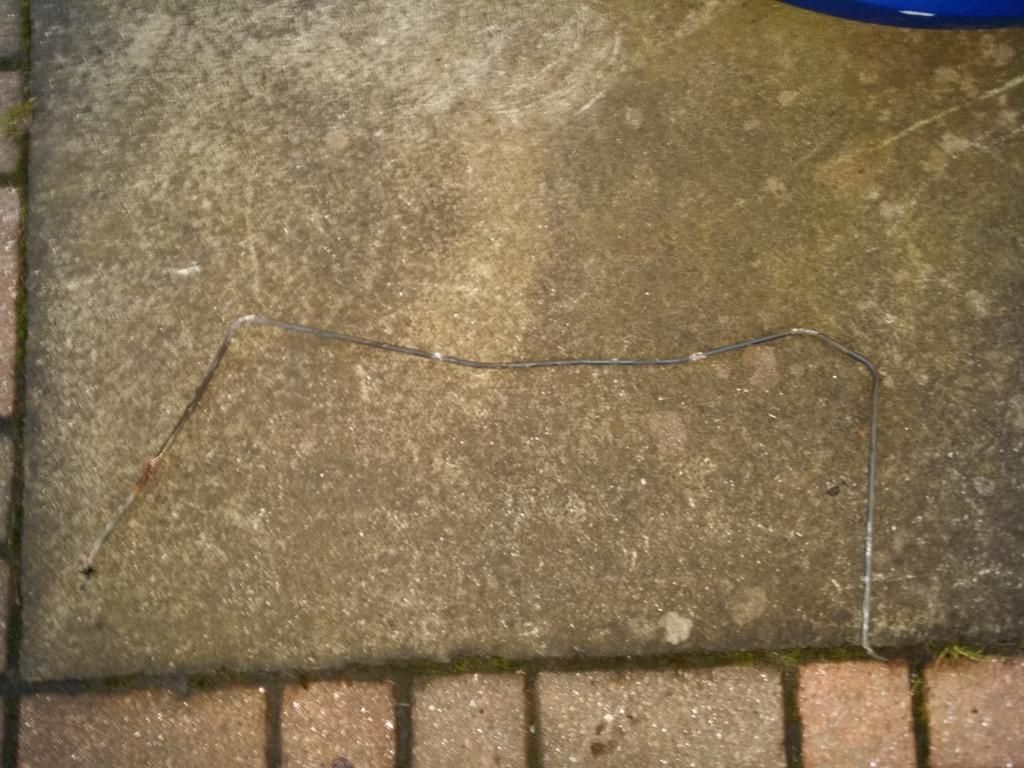

Measure the brake line that you have used using a piece of string or wire, so that you can follow the curves and get an exact measurement.

And now take the coil of new brake line and straighten enough to work with.

Measure enough of the new brake line, using the length of string/wire and cut using a pipe cutter. Remember to add the length of the unions you cut off. You can cut the line using other methods, but a good pipe cutter gives you a good end to flare with no crimping or distortion. You might also want to add a couple of inches, depending on how confident you are that you will get the flare right first time. You can always incorporate the extra length behind panels, but you cannot add length once cut without adding extra unions. Remember though that you need to add a little length for the flares, about 15mm will give you plenty.

Once you have cut the length of brake line you can lay it next to the old one and start adding bends and angles as needed. Don’t try and copy the tight bends of a factory item, just get it as close as possible.

You can use different methods to bend the brake line. You can get proper bending tools, or you can use a former of some sort. I used a large bolt to get reasonable bends. If you bend too tightly or quickly you can kink the brake line and then it is scrap. A kink in the line will restrict the flow of fluid when you press the brake pedal and will reduce your brake efficiency, if not stop it all together. Take your time and gradually bend it to a shape that you are happy with.

Once you have the correct length and correct shape you are ready to add the unions and flare the pipe. It isn’t unknown to flare the pipe and get it just right and then realise the union is still in your pocket. Dohhh.

Place the union on the brake line, with the threaded end facing the cut end, and then place the brake line in the correct size hole of the flaring tool. I judged the correct amount protruding by placing the flaring adaptor next to the line and making it flush with the shoulder.

You now need to tighten the flaring tool as tight as you can onto the brake line. The grip is important, otherwise the line will slip while you are flaring.

Then place the protruding part of the flaring adaptor into the brake line. If you have used a hacksaw or other method to cut the line, you may need to dress the end to get a good finish.

Place the clamp over the flaring tool with the cone located into the hole on the back of the adaptor and twist the whole clamp to locate it onto the tool.

Now screw the clamp down as far as it will go, so that the first flare is formed. The adaptor will be flush with the tool.

Now, unscrew the clamp and remove the adaptor

Now place the cone of the clamp directly into the newly formed flare and tighten it ½ to ¾ of a turn. This finishes off the flare and is known as a double flare, which is what you need.

Now remove the clamp, take the brake line out of the tool and check that the flare looks good and uniform. If it looks like it could pull through the union with a bit of force then it is too small.

Now flair the other end and the new brake line is finished and ready to fit.

This shows the new and the old lines together.

Fitting the new brake line is the reverse of the removal. Manipulate the line into place, and screw the new unions into place.

Push the line back into the 2 clips that were holding the original.

Make sure that the lines are not rubbing against anything or the bodywork. If they are rubbing then under the vibration of driving the lines could ware through after time, causing the line to rupture.

Refill the brake system with new brake fluid and bleed all 4 callipers until correct braking is achieved. After pumping the brakes for a while, check the new unions for any signs of leaking.

If you do not feel confident enough to work on braking systems then have the work carried out by someone experienced, or get them to check the system afterwards. The brakes are one of the most important systems on a car and not something you would want to get wrong.